- Company

- Product

- Application

- SMCC

- Service

- Responsibility

- Contact Us

6-35 kV XLPE Insulation Power Cable

This kind of cable is designed for the power transmission and distribution in the power grid with voltage up to the A.C.35kV. Compared with other power cables, the XLPE cable not only has excellent electric properties, mechanical properties, thermal-aging resistance property, chemical corrosion resistance, environmental stress resistance property, but also has virtue of simple construction, easy for installation,without the restriction of laying drop and the high temperature allowance for long term working, etc.

Standards:

1. GB/T12706.2-2008(Equivalent to IEC60502-1:2005) Rated Voltage 1kV(Um=1.2kV) to 35kV(Um=40.5kV) power cable with extruded insulation and accessories: Part 2: Rated Voltage 6kV(Um=7.2kV) to 30kV(Um=36kV) power cable;

2. GB/T12706.3-2008(Equivalent to IEC60502-2:2005) Rated Voltage 1kV(Um=1.2kV) to 35kV(Um=40.5kV) power cable with extruded insulation and accessories Part 3: Rated Voltage 35kV(Um=40.5kV) power cable;

3. GB/T19666-2005: General scope of flame retardant and fire resistant wire and cable.

Property of The Cable:

1. The highest long-term working temperature of the conductor is 90℃ ;

2. Earth Methods: Isolated neutral system, when single phase earthing, it could continuously running for 8 hours;

3. Short circuit time lasts no more than 5 seconds, the maximum temperature of the cable conductor is no more than 250℃ ;

4. Ambient temperature should be not lower than 0℃ for cable installation, the long-term working environment temperature is -20℃ to 45℃ ;

5. Installation: direct buried, overhead, in duct, in pipe, in channel, in suspended system, on bridge, up right, etc.

Package:

The cable has to be rolled neatened in the drum and package well, it should meet standard JB/T8137-2013, the cable end need to sealed, the cable end out of drum need to be protected by plastic cover and the length of out drum less 300mm. There has to be some necessary information on the cable package, such as: manufacturer name, cable name, size, rated voltage, quantity, quality, manufacturer date, standard and identify information and right rolled direction.

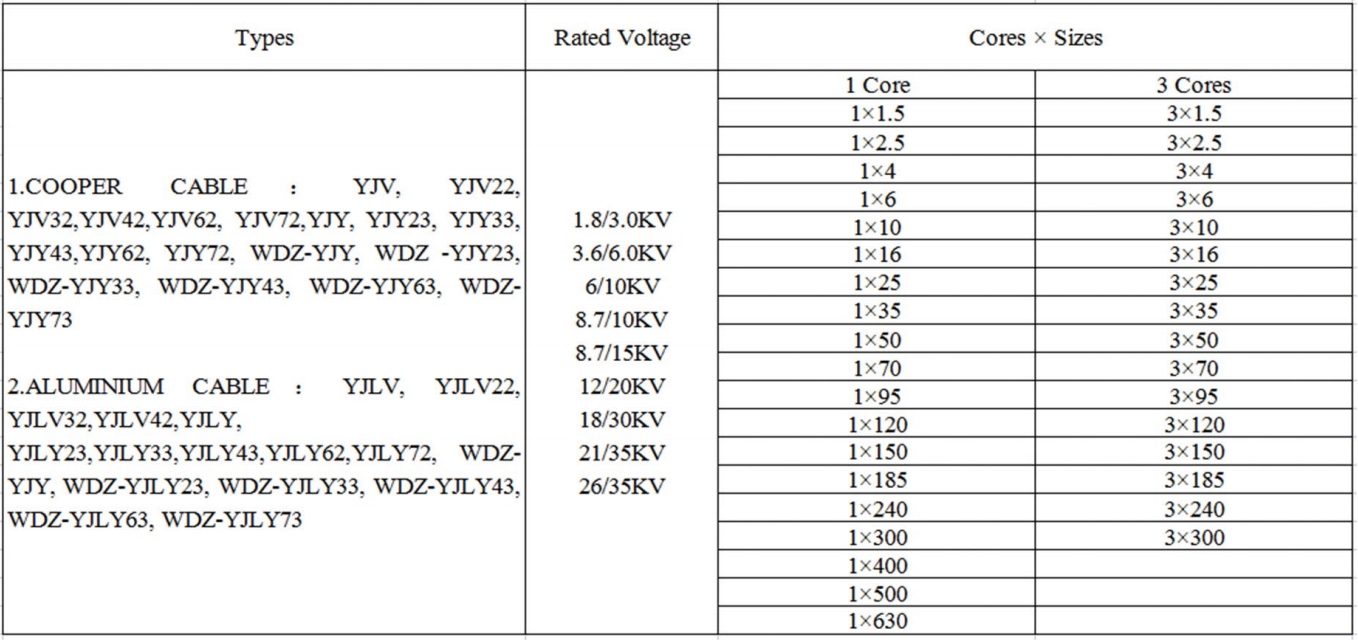

Type & Specification: