- Company

- Product

- Application

- SMCC

- Service

- Responsibility

- Contact Us

If you plan to invest in building a power station, you should first determine the structural form of the power station based on your actual situation and needs. The common structural forms of power station include Simple Cycle, Combined Cycle and Cogeneration/CHP. Here is a brief introduction:

Simple Cycle refers to a cyclic power generation system consisting of multiple internal combustion engines and generators independently, also known as an open cycle, which is a flexible and reliable power generation solution. Its advantages are fast installation, flexible start stop, and it is commonly used for power grid peak shaving, transportation, and industrial power systems. What is important is stable operation, high availability, fast start-up, reliable start-up, and fast transient load response capability.

The simple Cycle is commonly used in remote areas as a decentralized power generation facility, as well as as as an emergency or peak shaving unit. The power generation efficiency of internal combustion engines is generally 40-48%.

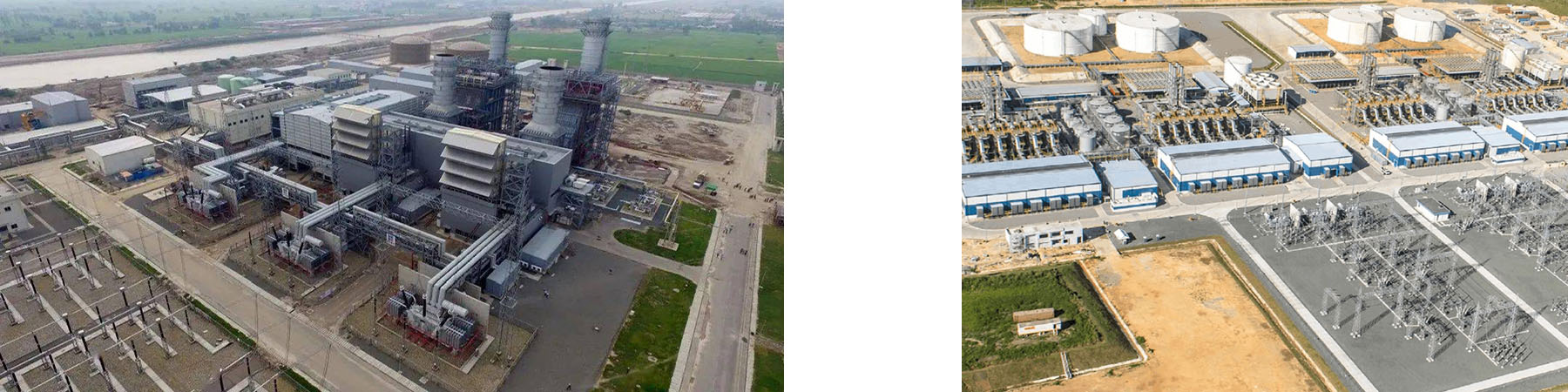

Combined Cycle is a cycle that combines two independent power cycles using different working fluids through energy exchange. The gas steam combined cycle is a cycle that combines the gas cycle (Brayton cycle) and steam cycle (Rankine cycle) by using high-temperature exhaust gas from a gas turbine (or gas internal combustion engine) to produce steam in a waste heat boiler, which is then sent to the turbine to do work.

The combined cycle power station is a cyclic power generation system composed of a gas turbine, a generator, a waste heat boiler, a steam turbine, or a heating steam turbine. It recovers and converts the high-temperature exhaust gas discharged from the gas turbine into steam through the waste heat boiler, and then injects the steam into the steam turbine for power generation, or uses some of the exhaust steam after power generation for heating. The combined cycle is mainly used for power generation and cogeneration, with a power generation efficiency of over 50%.

Cogeneration/CHP refers to the simultaneous generation of electricity and useful heat, that is, the use of waste heat from power generation to produce useful steam or hot water for industrial manufacturing, civil heating, etc. It can also use waste heat from power generation or industrial manufacturing to produce steam power generation, achieving the goal of maximizing energy utilization. Combined cooling, heating, and power (CCHP) refers to the simultaneous generation of electricity, heat, and cold. The two technological solutions of cogeneration and cogeneration are comprehensive, efficient, cost-effective, and environmentally friendly. They are widely used in distributed energy projects and have made important contributions to global energy demand.

Cogeneration is a circulation system composed of an engine, a generator, and a waste heat boiler. It is a form of recovering high-temperature exhaust gas discharged from the engine through a waste heat boiler and converting it into steam or hot water for utilization. During the operation of the generator set, different temperatures of waste heat and exhaust gas are generated. The exhaust temperature of high-speed internal combustion engines is around 520 ℃, that of medium speed internal combustion engines is about 354 ℃, and that of gas turbines is as high as 550 ℃, resulting in a heat loss of about 36%. The temperature of the generator cooling water reaches 100 ℃, with a heat loss of about 28%. In order to fully utilize thermal energy and turn waste into treasure, we provide different technologies based on the working principle, structure, performance, and characteristics of the generator to convert the waste heat into usable energy forms.

The advantages of cogeneration:

1. Reduce energy costs by utilizing energy more effectively;

2. Improve environmental quality by reducing pollutant emissions;

3. Waste heat recovery is widely used for sustainable thermal applications;

4. Flexibly respond to changes in heat and electricity demand.